often referred to as caulking guns or glue guns, are essential tools in various industries, including construction, automotive, and arts and crafts. These tools are designed to dispense adhesive materials efficiently and precisely, making them indispensable for tasks that require bonding, sealing, or filling. In this blog, we will explore the functions, types, and applications of adhesive applicator guns, as well as their advantages, maintenance, and tips for effective use.

1. Introduction to Adhesive Applicator Gun

Adhesive applicator guns are versatile tools used to apply sealants, adhesives, and other materials from cartridges or tubes. They provide a controlled and consistent flow, which is crucial for achieving a clean and professional finish. The development of these guns has revolutionized how adhesives are applied, allowing for more precision and efficiency in various projects.

2. Types of Adhesive Applicator Guns

There are several types of adhesive applicator guns, each designed for specific applications and materials. Understanding the differences between these types can help you choose the right tool for your needs.

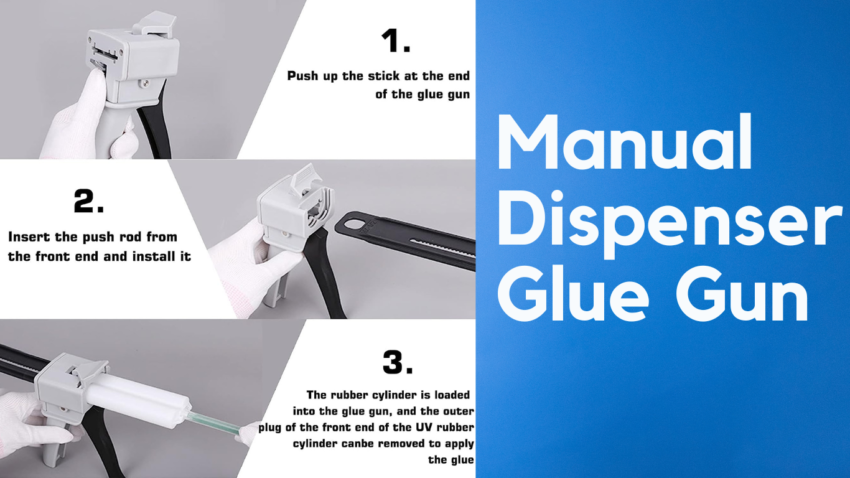

Manual Caulking Guns

Manual caulking guns are the most common type and are operated by hand. They consist of a trigger mechanism that pushes a plunger into the back of a cartridge, forcing the adhesive out through the nozzle. These guns are ideal for small to medium-sized projects and are available in various sizes to accommodate different cartridge capacities.

Pneumatic Caulking Guns

Pneumatic caulking guns are powered by compressed air, which makes them suitable for large-scale projects that require continuous and fast application. These guns are more efficient than manual ones and reduce hand fatigue, making them ideal for professional use.

Electric Caulking Guns

Electric caulking guns are powered by batteries or electricity and offer the convenience of continuous operation without the need for manual force or compressed air. They are ideal for medium to large projects and provide a consistent flow of adhesive.

Hot Glue Guns

Hot glue guns use thermoplastic adhesive sticks that are melted by an internal heating element. The melted adhesive is then dispensed through a nozzle. These guns are commonly used in arts and crafts, as well as in light industrial applications. They come in various sizes and temperature ranges to accommodate different materials and bonding requirements.

3. Key Functions of Adhesive Applicator Guns

Adhesive applicator guns serve several key functions, making them indispensable in many tasks:

- Precision Application: They allow for precise control over the amount and placement of adhesive, ensuring clean and accurate application.

- Efficient Dispensing: These guns provide a consistent flow of adhesive, reducing waste and improving work efficiency.

- Versatility: Adhesive applicator guns can be used with a wide range of adhesives and sealants, including silicone, latex, polyurethane, and hot glue.

- Ease of Use: They simplify the application process, making it easier for both professionals and DIY enthusiasts to achieve high-quality results.

- Reduced Fatigue: Powered models reduce the physical effort required, minimizing hand and wrist fatigue during prolonged use.

4. Applications of Adhesive Applicator Guns

Adhesive applicator guns are used in various industries and applications. Some of the common uses include:

- Construction and Building: Applying sealants around windows, doors, and other joints to prevent air and water leakage.

- Automotive: Sealing seams and joints, as well as applying adhesives for trim and body repairs.

- Arts and Crafts: Bonding materials such as paper, fabric, and wood in creative projects.

- Manufacturing: Applying adhesives in assembly processes for products like electronics, appliances, and furniture.

- Home Improvement: Sealing gaps and cracks, installing fixtures, and performing repairs around the house.

5. Advantages of Using Adhesive Applicator Guns

Using adhesive applicator guns offers several advantages over manual application methods:

- Improved Accuracy: The precise control of adhesive flow ensures neat and accurate application, reducing the need for cleanup and touch-ups.

- Increased Efficiency: The consistent dispensing rate speeds up the application process, allowing for faster completion of projects.

- Enhanced Durability: Proper application of adhesives enhances the durability and longevity of the bonded materials.

- Cost-Effectiveness: Reduced waste of adhesive materials translates to cost savings, especially in large projects.

- Versatile Use: The ability to handle various adhesives and sealants makes these guns suitable for multiple applications, reducing the need for multiple tools.

6. Maintenance and Care of Adhesive Applicator Guns

Proper maintenance and care of adhesive applicator guns are essential to ensure their longevity and optimal performance. Here are some tips to keep your gun in good condition:

- Regular Cleaning: Clean the gun thoroughly after each use to prevent adhesive buildup, which can clog the nozzle and affect performance.

- Lubrication: Apply lubricant to moving parts to ensure smooth operation and prevent rust and corrosion.

- Inspection: Regularly inspect the gun for any signs of wear or damage, such as cracks or loose parts, and replace or repair as needed.

- Storage: Store the gun in a cool, dry place to prevent damage from moisture and extreme temperatures. Use protective cases or covers if available.

- Proper Usage: Follow the manufacturer’s instructions for loading and using the gun, and avoid overloading or using incompatible materials.

7. Tips for Effective Use of Adhesive Applicator Guns

To achieve the best results with your adhesive applicator gun, consider the following tips:

- Choose the Right Gun: Select the appropriate type of gun based on the adhesive material and the size of the project.

- Prepare the Surface: Ensure the surface to be bonded is clean, dry, and free of debris or contaminants.

- Cut the Nozzle Properly: Cut the nozzle at the right angle and size to control the flow of adhesive according to the specific application.

- Apply Steadily: Apply steady pressure on the trigger to ensure a consistent flow of adhesive. Avoid sudden stops or starts to prevent gaps or uneven application.

- Smooth the Bead: Use a smoothing tool or your finger (with appropriate protection) to smooth out the adhesive bead for a clean finish.

- Follow Cure Times: Allow the adhesive to cure for the recommended time before subjecting it to stress or load.

8. Conclusion

Adhesive applicator guns are invaluable tools that offer precision, efficiency, and versatility in applying various adhesives and sealants. Whether you are a professional in the construction industry or a DIY enthusiast working on home improvement projects, these tools can help you achieve high-quality results with ease. By understanding the different types of guns, their functions, and proper maintenance, you can maximize their benefits and ensure successful application in all your bonding tasks.